Keeping it simple – US Strategic Minerals Exploration’s path to Commercial Carbon Capture

As we enter a new chapter in the fight to save our planet, one should step back and see how far we have come since the 1992 Kyoto Protocol was signed by developed nations to reduce global carbon dioxide emissions. Human-caused carbon dioxide has contributed to the increase in atmospheric CO₂ levels from 280 ppm in the 1800s to over 400 ppm when the Paris Climate Change Agreement was signed in 2015. CO₂ emissions from fossil fuel burning power plants have been an accepted cause of the resultant 1-2 degree Celsius rise in global atmospheric temperature noted since the early 1900s. For much of the human population in the 195 countries that signed the Paris Climate Agreement, non-renewable baseload electric power and natural gas used for home heating are taken for granted. In the worldwide effort to reduce GHG emissions, a shift toward renewable energy sources has taken center stage, commanding an incredible amount of legislative focus from governments, academia, and private industry. Global climate change initiatives and the necessary ESG awareness will escalate in importance and scale through this decade and beyond. At US Strategic Minerals Exploration, we are committed to meeting this challenge head-on. This blog will discuss US Strategic’s path to commercial carbon capture.

How can the application of US Strategic’s CCUS technology permanently sequester CO₂?

Very simply, we will use Nature’s own chemistry process in a controlled reaction that results in the precipitation of valuable carbonate minerals. This chemical process, which permanently stores CO₂ in alkaline earth carbonates, is termed Ex-Situ Mineral Carbonation in the scientific community. Our challenge is to commercialize this CCUS technology in a scalable fashion, such that a meaningful volume of CO₂ can be permanently and economically removed from the earth’s atmosphere. The simplicity of this natural chemical process should not be overstated, since to date, the full cycle commercialization of this type of carbon capture has been an elusive prize.

How do we propose to use Nature’s own chemistry process in a scalable CCUS processing plant in a commercially viable business setting that has worldwide application? That is the multi-million-dollar question. The answer will come after focusing the efforts of many creative minds toward a worthy goal which, when reached, will help us to “Save Our Planet”.

Physical chemistry is not just a roadblock to a mineral engineering degree!

In pursuing a bachelor’s degree in engineering, the required Organic and Physical Chemistry credits were widely viewed as better suited for the advanced degrees and post-docs. The satisfaction of solving a drilling or production problem in the oilfield or finding a cheaper way to mine and process ore had immediate, measurable results that could positively impact the bottom line. As our careers evolve, our on-the-job experiences tend to diminish the relevance of what we learned in college and through certified training courses. When we are forced to think outside the box or pivot mid-career, the innovator uses their mind and unique inner creativity to solve problems that might have otherwise persisted for decades.

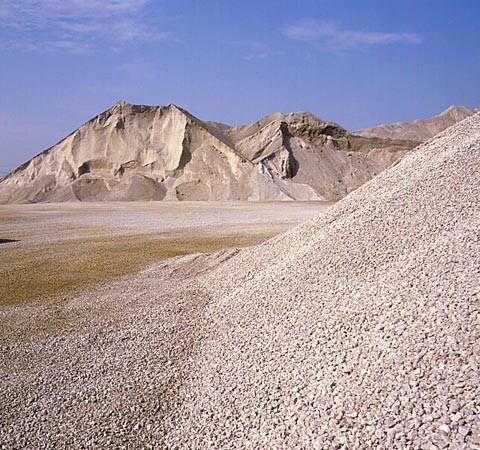

In a simple explanation of our CCUS technology, Nature’s clues have been at our feet since the time humans walked on the earth. The existence of carbonated gravel created naturally from chemical processes (weathering) of rock formations that have direct exposure to the atmosphere gives us a clue to Nature’s version of an Ex-Situ Mineral Carbonation process.

The exposure of certain minerals to atmospheric CO₂ dissolved in groundwater can create a solution of cations seeking Calcium and CO₂ which ultimately result in the formation of limestone, dolomite,

travertine, etc. To speed up Nature’s process, which occurs over millions of years, our unique approach uses basic mineral processing techniques that incorporate reagents commonly used for pH control in conjunction with proprietary catalysts.

An important question we as innovators face is how to produce a widely used product, and concurrently, one that can utilize widely available feedstock and a significant amount of human-caused CO₂. At our Utah brine mining project, where we have targeted a highly concentrated Calcium and Magnesium mineral brine source, we can provide all three legs of the proverbial barstool. Finally, by producing a high purity product for sale into a specialty mineral market, our goal of commercializing carbon capture is complete! If you are interested in participating in our project in Utah or just as importantly the development and scale-up of this type of carbon capture process, visit our website!

#USStrategicMineralsExploration #CCUSTechnology #CCUS #ESGStandout #LiquidOre™ #StrategicMinerals #HybridExplorationApproach #CarbonCapture #EarthScience #ClimateChange